That everything revolves around development,is something we at Fuel Saving Technology Ltd. no as no other! Our expert team does extensive technical research when a new model or engine type is released. We look at the engine on a technical level,for example at the powertrain,but also at what kind of gear box has been installed. Aside from these,the injection system and coupling are very important and with turbocharged petrol and diesel engines the applied turbo is very important.

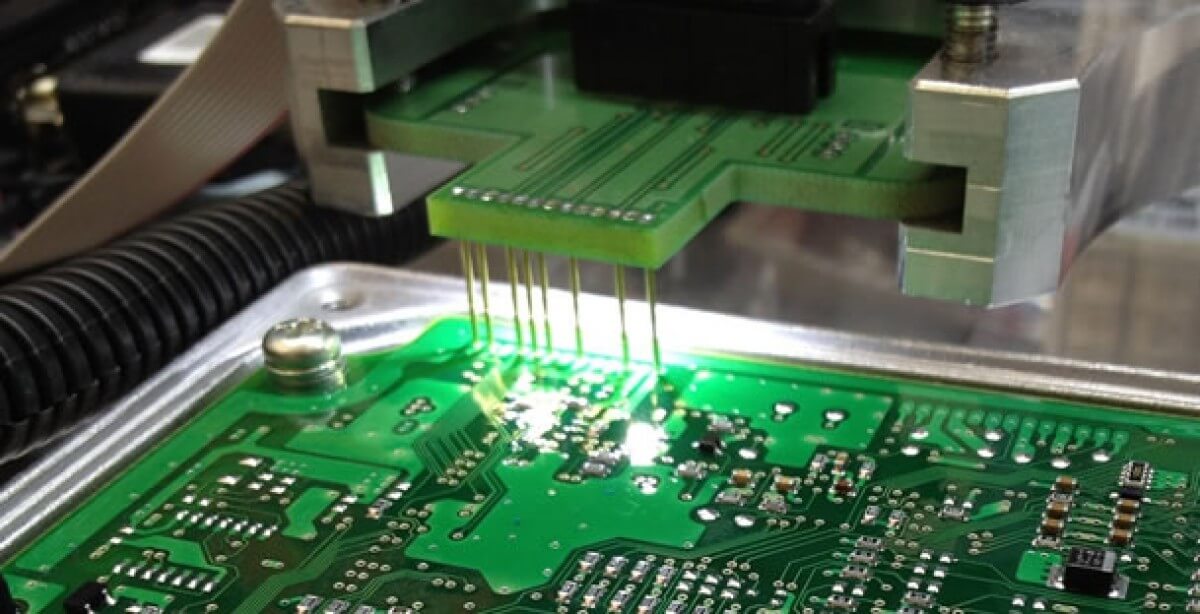

After the research stage,we start work on reading the standard engine software. If it concerns a known injection system,the reading doesn’t take much time. However,if it is a new type of injection system,we must first programme new protocols for the software in order to communicate with the ECU. This is essential as data has to be read and written. In the last few years,this has entailed more and more work. Not so much because manufacturers are opposing this,but mostly because the technology is becoming more extensive and more data is processed in the ECU. Once the original software has been read,it is examined and completely analysed. This determines where the important ignition maps are,such as load pressure,turbo,accelerator injection,torque limiter,speed limiter and injection control.

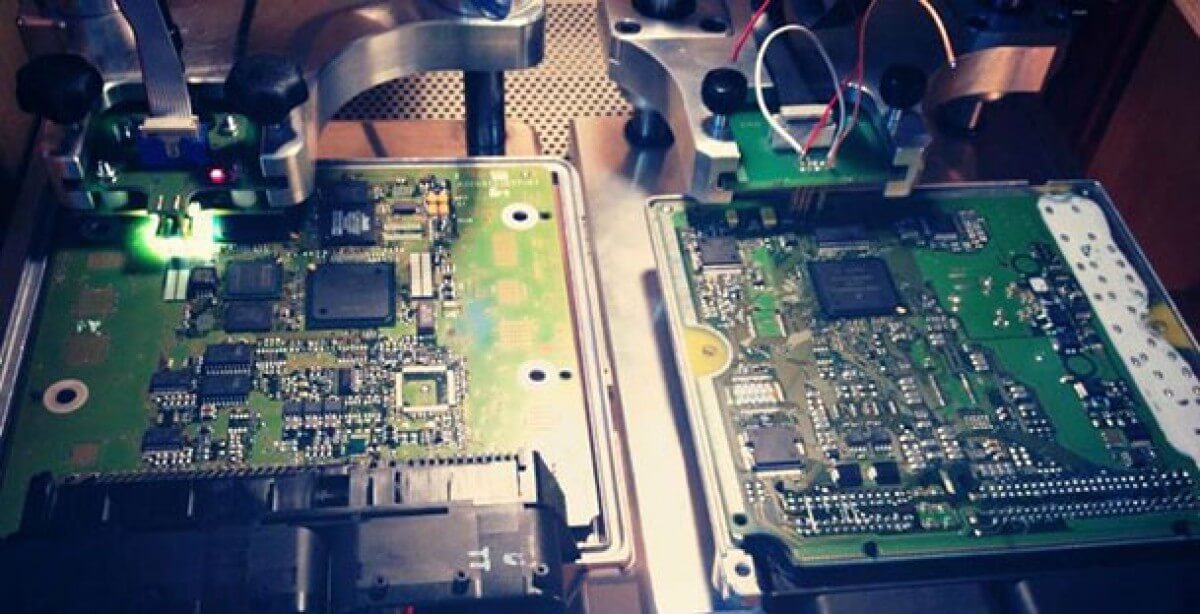

As soon as we receive a new vehicle,we will test it in its original state on our test bench with diagnostic equipment. This way,we can look if the requested ECU values are actually achieved with regard to the given values.

Our team of software developers gets to work on optimising the engine software. First,a back-up of the read software is made,so that we can use this should this become necessary. Next,we adapt the software parameters of the ECU. The parameters are adjusted to another for optimal effect. With measuring equipment all adaptations are calibrated,which allows us to guarantee an optimal mixture between air and fuel mixture. This makes your vehicle more powerful,smoother and efficient! By adjusting the software directly in the ECU,we maintain the best and safest achievements. The adjustment is within the safety margins set by manufacturers. This assures you of a safe and long-lasting optimisation.

The development of software is done on a power bench. For this,we use the facilities of DAF dealer Sent Waninge B.V. During optimisation on the test bench we can read and log all important parameters in real time. By way of the diagnostic equipment the values of the turbo and injection system are continuously calibrated. We also take into account the mechanical and thermic load of both the engine and powertrain when dealing with the software,making sure it aligns perfectly with the original software. During development several measurements take place. For example,on the test bench we continuously check the fuel mixture,the turbo pressure,inlet and outlet temperature,injection quantity and the injection itself. ECO Setting is carefully and extensively tested,making it of excellent quality. The software complies with TÜV and DEKRA requirements. ECO Setting guarantees that the live span of the engine is not adversely affected.

With the help of extra measuring equipment on the vehicle,we head out onto the road to test everything in practice. On a power bench,drive ability can’t be seen. After uploading the software,the vehicle immediately switches to the new parameters. You instantaneously experience the improved performance!

Do not hesitate and contact us now.

Contact us.